Pig farming is a true balancing act, marked by the constant challenge to formulate cost-effective diets while keeping health and performance high. High ingredient prices and rising gas prices have led to marked increases in feed prices, making feed an even larger proportion of pig production costs. Low-cost (alternative) ingredients may look attractive and are sometimes a necessary option.

Yet the variable quality and nutritional values that often come with low-cost raw materials may result in decreased feed efficiency rates and lower growth; a low-cost diet on paper can turn into an expensive diet in practice. This article explores pellet optimisation and protein and energy utilisation to better control and improve diets and associated production costs.

Optimising pelleting processing

Feed millers have been confronted with sharp increases in gas and electricity prices, which have in turn increased the overall manufacturing cost of feed. While many steps in feed production require energy, pelleting feed uses up to 60% of the total energy. Providing pigs with pelleted feed over meal is recommended, as it improves feed efficiency and nutrient digestibility. Trials showed that pelleted feed resulted in up to 9% improvement in feed conversion ratio (FCR) in nursery pigs and 5.5% improvement in finishing pigs when compared to pigs that received meal diets. A high pellet quality is required to realise these benefits of pelleted feed. But with the high feed and energy prices, is it still cost-effective to pellet the feed, or is meal now a more economical alternative?

Trials and expertise by Cargill Animal Nutrition showed that there is a tipping point. At a feed price of € 440/tonne and an energy price of € 0.40/kWh, the production cost per kg of weight gain is pretty much the same between pelleted feed and meal, despite the feed efficiency gains of pelleted feed having been taken into account. To continue to capture the benefits of using pelleted feed, the cost of pelleting and pellet quality should be carefully controlled and improved where possible.

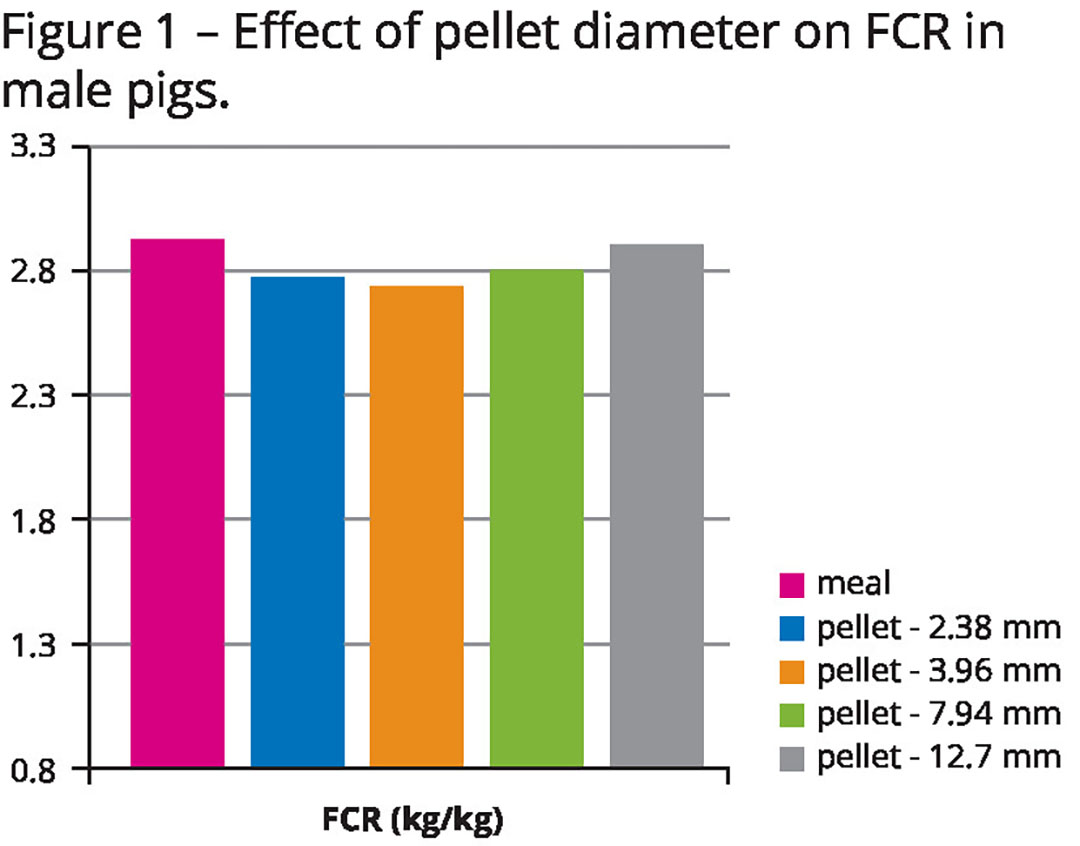

Improvement in feed production energy use can be obtained through formulation adjustments (the amount of fat, starch, glycerol and binders in the mash) and optimising pellet diameter, throughput and temperature. For example, increasing pellet diameter from 2.5 mm to 3.5–4.5 mm can save 11% on energy use without affecting performance. A trial in 57–112 kg barrows showed there was no difference in FCR between pellets with a diameter ranging from 2.38 mm to 7.94 mm (Figure 1).

Safely reducing protein

Successful pig production relies on efficient and cost-effective use of inputs. Protein ingredients can be expensive; if the protein is digested better and fewer nutrient losses take place, protein level reduction can be considered. This has led Cargill Animal Nutrition to develop Aminoreach, a complementary feed whose active compounds improve the digestion of dietary crude protein (CP) and amino acids. It also helps to reduce the flow of undigested protein in the gut, an important driver for intestinal health. Using less CP can also help to reduce nitrogen excretion in pigs.

Better protein utilisation and flow can enable a reduction of diet CP levels, thus reducing diet cost while maintaining the same level of performance. A diversity of protein sources, for example to replace soybean meal, can be leveraged to reduce feed cost while matching pigs’ requirements at all life stages in a sustainable way.

This nutritional solution comes with a well-established matrix for amino acids and net energy. Formulation simulations done with soybean meal (at € 559/tonne) showed that more than € 3/tonne of compound feed, used for grower/finisher diets, can be saved.

Improving energy utilisation

Protein ingredients can be expensive, but the same is also true for energy-rich ingredients. A high and efficient energy utilisation is important to ensure more nutrients from feed are used for growth, improving FCR, lowering overall rearing costs and increasing margins per finished pig. ConverMax is a natural feed supplement with a blend of botanical extracts and high-quality mineral sources.

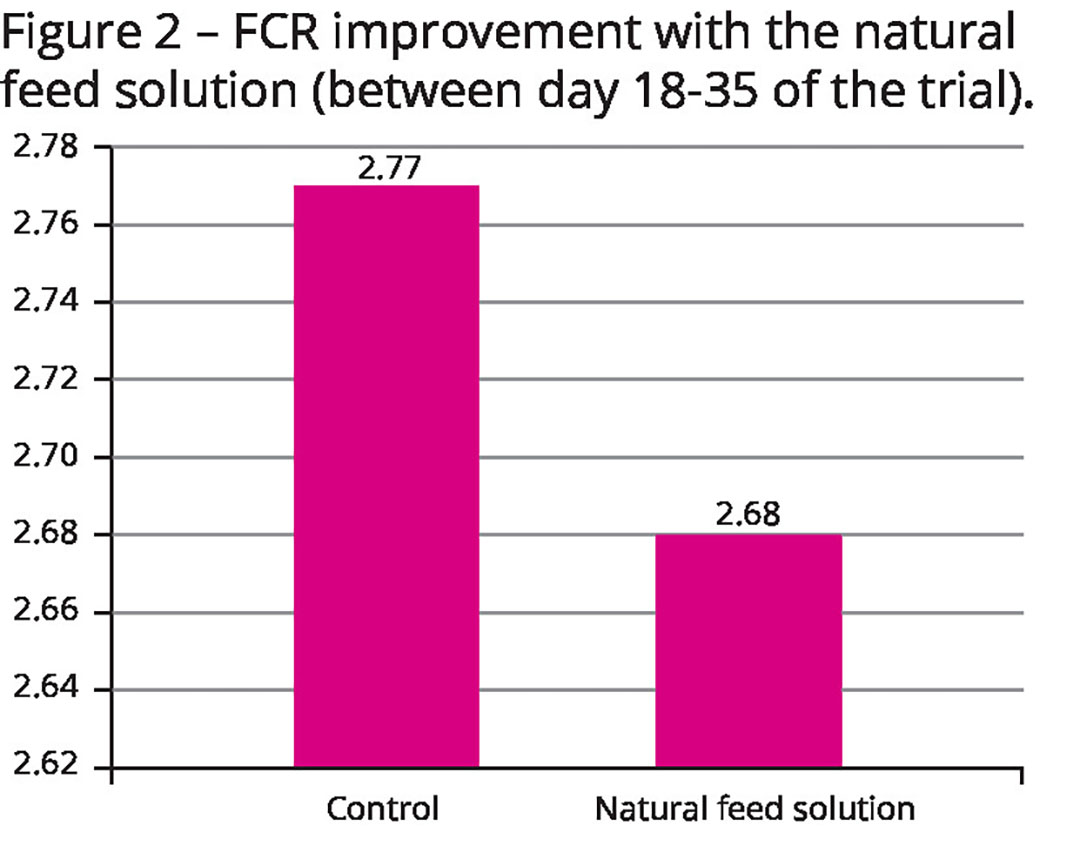

It has been included in the diets of approximately 7 million finishing pigs across Europe since 2020 and is now included in grower-finisher diets in at least 10% of units in the UK. A recent trial in the UK (2022) revealed an overall batch improvement in FCR of 0.08 for finishing pigs, with a significant improvement (Figure 2).

Overall, this delivered an improvement of € 3.97 in margin per finished pig. Results from the UK trial were comparable to those observed in Spain, where a saving in feed cost of € 2.28 per pig was achieved. The natural feed solution also promotes increased levels of inactive behaviour, which helps to reduce skin and carcass damage and makes sure that less energy and nutrients are wasted on negative behaviour and nervousness, hence supporting better energy utilisation.

Conclusion

With today’s challenges in pig farming including high production costs, the European zinc oxide ban, environmental regulations and further reductions on the use of antibiotics, the focus on health and nutrition in pigs is even more important. This makes feed processing and diet formulation more complex.

Cargill Animal Nutrition has the products and the expertise to help feed millers and farmers cope with increasing production costs by increasing digestibility and utilisation of energy and protein, combined with keeping pellet quality high. In conclusion, while it is difficult to control the energy and raw material markets and associated price increases, it is still possible to have an impact on feed processing and nutrition at the animal level. Even small adjustments can make a big difference.

link

:max_bytes(150000):strip_icc()/Best-Condiments-for-Better-Blood-Sugar-According-to-Dietitians-aa44e694e2324a269ad75f1518d40d2f.jpg)